-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

In the realm of thermal management and energy efficiency, Heat Flux Sensors have emerged as indispensable tools for engineers and researchers alike. These sensors are designed to measure the rate of heat transfer per unit area, providing critical data that can enhance the performance of various projects. Whether it's optimizing industrial processes, improving the design of HVAC systems, or enhancing building insulation, the accurate and reliable data generated by Heat Flux Sensors can lead to significant advancements in energy conservation and thermal analysis.

To maximize the potential of these sensors, it is essential to employ them effectively in your projects. Understanding the proper installation techniques, calibration procedures, and data interpretation methods can greatly influence the quality and applicability of the collected data. Additionally, considering the environmental conditions and the specific objectives of your project can further enhance the effectiveness of Heat Flux Sensors. This guide outlines the top 10 tips for utilizing these sensors to their fullest, ensuring that your projects benefit from precise heat transfer measurements and ultimately, improved energy efficiency.

Heat flux sensors are crucial devices that measure the rate of heat transfer per unit area, providing valuable insights into thermal processes across various applications. Based on the principles of thermodynamics, these sensors work by detecting temperature differences across conductive materials. According to the International Energy Agency, optimizing heat transfer measurements can result in energy efficiency improvements of up to 30% in industrial settings. This remarkable potential underscores the importance of understanding the sensor's operational principles to implement them effectively in projects.

In practical applications, heat flux sensors can be utilized in various fields, including building energy management, thermal insulation assessment, and process monitoring in manufacturing. For instance, a report from the U.S. Department of Energy highlights how integrating heat flux measurements in building designs can lead to better energy performance and enhanced occupant comfort. In manufacturing, real-time heat transfer monitoring helps in refining processes such as welding and casting, leading to improved product quality and reduced waste. Thus, grasping the principles of heat flux sensors is essential for leveraging their capabilities and achieving significant advancements in thermal management practices.

| Tip Number | Tip | Explanation | Application Area |

|---|---|---|---|

| 1 | Select Appropriate Sensor Type | Different types of sensors are suited for different applications. Choose based on measurement range and sensitivity. | Research, Industrial Applications |

| 2 | Calibrate Regularly | Ensure your sensors provide accurate readings by calibrating them at consistent intervals. | Quality Control, Research |

| 3 | Minimize Thermal Interference | Position sensors away from heat sources that can affect readings, including other electronic devices. | Lab Testing, HVAC Systems |

| 4 | Use Proper Mounting Techniques | Ensure that sensors are mounted securely to avoid movement which can lead to inaccurate measurements. | Construction, Manufacturing |

| 5 | Understand Sensor Limits | Be aware of the maximum and minimum thresholds of your sensors to avoid damage and ensure reliability. | All Applications |

| 6 | Utilize Data Logging | Implement data logging techniques to analyze trends over time and improve overall efficiency. | Research, Field Studies |

| 7 | Integrate with Other Sensors | Combine heat flux measurements with temperature and humidity sensors for comprehensive analysis. | Climate Research, Environmental Monitoring |

| 8 | Data Visualization | Use graphical presentations of heat flux data to enhance understanding and communication of results. | Reporting, Presentations |

| 9 | Stay Updated on Technological Advances | Regularly review new sensor technologies that may provide improved performance for your applications. | All Applications |

| 10 | Collaborate with Experts | Engage with professionals who have experience in heat flux measurement for insights and best practices. | Consulting, Research Projects |

When selecting heat flux sensors for your projects, certain key specifications are paramount to ensure optimal performance and accuracy. First and foremost, consider the sensor's thermal response time. This specification indicates how quickly the sensor can respond to changes in temperature, which is crucial in applications requiring real-time data. A faster response time allows for more accurate readings in dynamic environments, making it essential for applications involving rapid temperature changes.

Another significant aspect to evaluate is the measurement range and sensitivity of the heat flux sensor. Different projects may demand varying levels of sensitivity depending on the materials and conditions being tested. A sensor that can accurately measure a wide range of heat flux values ensures that it can be adapted to different scenarios without compromising precision. Additionally, look into the calibration standards of the sensor; ensuring that it is certified and adheres to industry benchmarks can enhance its reliability and data integrity in critical applications.

When positioning heat flux sensors in your experimental setup, the accuracy of your measurements significantly hinges on their placement. One critical practice is to install the sensors on a flat surface to ensure uniform contact and reliable heat transfer readings. Avoid placing sensors in areas with potential thermal interference from other components, as this can lead to erroneous data. Additionally, it is vital to ensure that the sensors are calibrated correctly before each experiment to account for any variations in environmental conditions or material properties.

Another essential tip is to employ proper mounting techniques. Secure the sensors firmly using appropriate adhesives or fixtures that can effectively withstand the operational environment without compromising the sensor’s integrity. It’s advisable to align the sensors in the same direction as the heat flow to capture the most accurate readings. Finally, consider the surrounding materials; the thermal conductivity of these materials can impact the sensor’s performance, so understanding the context in which the sensors operate is crucial for obtaining reliable results.

When it comes to effective data acquisition for heat flux measurements, leveraging the right techniques is essential. Properly setting up your sensors is critical to ensure accurate readings. One of the key tips is to ensure proper thermal contact between the sensor and the surface being monitored. This can significantly reduce measurement errors and improve the reliability of the data collected.

Another important aspect of data acquisition is the calibration of your sensors. Regular calibration ensures that measurements remain accurate over time. It is advisable to create a calibration schedule that aligns with your project needs and the environmental conditions under which the sensors operate. Additionally, always document the calibration process meticulously to track the performance and adjustments made to the sensors.

Lastly, consider employing advanced data logging techniques. Utilizing high-frequency sampling can capture transient heat flux events that might be missed with lower sampling rates. This is particularly useful in applications where rapid changes in heat flux are expected. Implementing real-time data monitoring can also help in troubleshooting and ensuring that your measurements are within expected ranges, providing ongoing assurance of data integrity throughout your project.

This chart illustrates the heat flux measurement (in W/m²) across different materials (Concrete, Wood, Steel, and Insulation) using heat flux sensors. The data represents typical values that can be encountered in various applications.

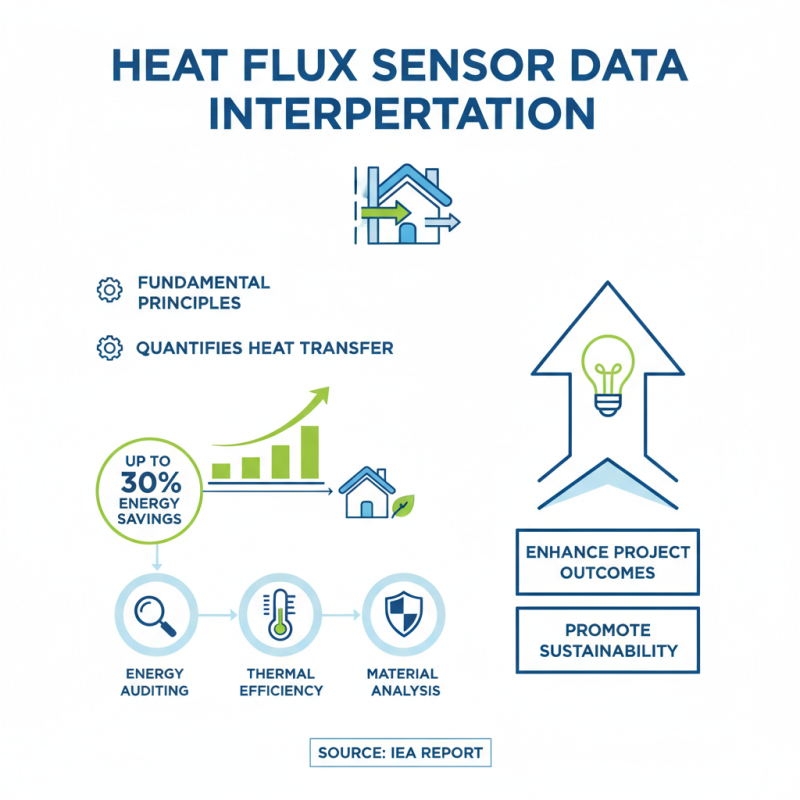

Interpreting results from heat flux sensors requires a strong grasp of the fundamental principles behind their operation. These sensors quantify the heat transfer occurring across a given surface, providing crucial data that helps in energy auditing, thermal efficiency assessments, and material performance analysis. According to a report by the International Energy Agency, accurately measuring heat flux can result in energy savings of up to 30% in residential buildings by identifying areas of thermal inefficiency. Thus, effective analysis of this data not only enhances project outcomes but also promotes sustainable practices in engineering and construction.

When analyzing the collected data, it’s important to account for environmental conditions, sensor calibration, and the specific heat transfer mechanisms at play. For instance, a study published in the Journal of Building Physics highlights that dynamic changes in outdoor temperature can significantly influence the readings from heat flux sensors. Engineers must be adept at interpreting these fluctuations to differentiate between genuine thermal losses and anomalies caused by external conditions. Additionally, employing advanced data processing techniques, such as machine learning algorithms, can help in identifying patterns and predicting future thermal behaviors, leading to more informed decisions in project development and design.