-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

In recent years, the importance of accurate measurement and control of air flow has become increasingly recognized across various industries, leading to a surge in demand for Air Flow Meters. According to a report by MarketsandMarkets, the global air flow meter market is expected to reach approximately $5.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026. This growth is driven by the rising need for automation in various sectors, including HVAC, automotive, and manufacturing, where maintaining efficiency is crucial for operational success. Understanding the various types of Air Flow Meters, their applications, and the latest technological advancements can empower businesses to optimize their processes, reduce energy consumption, and improve overall productivity. This guide aims to delve into the fundamental aspects of air flow measuring devices and provide comprehensive insights that can enhance efficiency for your specific applications.

When selecting an air flow meter, several critical factors must be considered to ensure optimal efficiency in your applications. First, the type of meter—whether it’s a thermal, differential pressure, or positive displacement meter—should align with the specific requirements of your system. Each type operates differently and is suitable for various conditions, such as temperature, pressure, and flow range. Understanding the characteristics of your application will lead you to the most effective choice.

Moreover, accuracy and calibration are paramount considerations. The air flow meter's accuracy can significantly impact the overall performance of your system, particularly in processes where precise measurements are vital. It is essential to evaluate the meter’s specifications and ensure it can be calibrated to meet the industry standards required for your application. Additionally, factors such as installation space, maintenance needs, and the environmental conditions where the meter will operate should also influence your decision. By considering these key elements, you can enhance the efficiency of your air flow measurements and support your operational goals effectively.

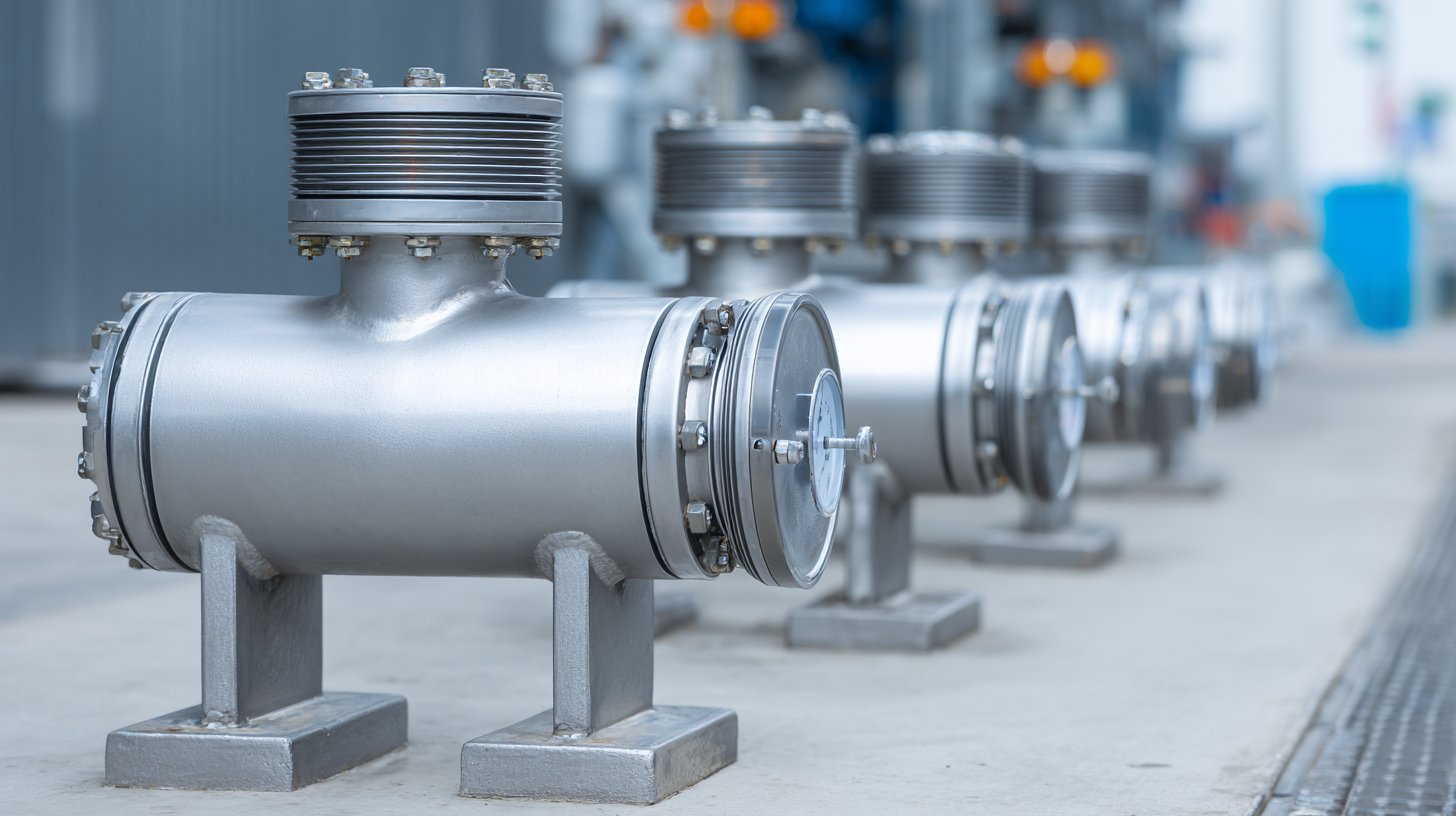

Air flow meters are essential instruments used in various industries to measure the flow of air efficiently. Understanding the different types of air flow meters helps in selecting the right one for specific applications. The primary types include thermal mass flow meters, differential pressure flow meters, and volumetric flow meters, each with its distinct advantages. For example, thermal mass flow meters are known for their high accuracy and responsiveness, making them ideal for applications in HVAC systems or clean rooms where precise measurements are crucial.

Differential pressure flow meters, on the other hand, are favored in large industrial setups where cost-efficiency and robustness are paramount. They function based on the pressure drop across a flow restriction and are widely used in applications like compressed air systems and ventilation networks. Lastly, volumetric flow meters, often used in laboratories and research settings, provide direct measurements of the volume of air flowing through a system, thus ensuring reliability in data collection for various experimental processes. Understanding these types enables industries to enhance productivity and optimize performance in their air flow management systems.

Accurate air flow measurement plays a crucial role in optimizing energy efficiency and reducing operational costs across various industries. By employing air flow meters, businesses can obtain precise data on air consumption and distribution, which is essential for ensuring that systems operate at peak efficiency. When air flow is properly measured and monitored, it allows for timely adjustments and corrections in processes, resulting in significant energy savings.

Furthermore, understanding the nuances of air flow helps identify areas where improvements can be made, such as upgrading equipment or enhancing ventilation systems. This not only leads to lower energy costs but also contributes to a more sustainable operation by minimizing waste. Ultimately, incorporating accurate air flow measurement techniques fosters an environment of continuous improvement, enabling organizations to maintain competitive advantage while promoting responsible energy usage.

| Application | Flow Meter Type | Accuracy (%) | Energy Savings ($/year) | Operational Cost Reduction ($/year) |

|---|---|---|---|---|

| HVAC Systems | Thermal Mass Flow Meter | 1.5 | 1500 | 800 |

| Industrial Ventilation | Vortex Flow Meter | 2.0 | 2000 | 900 |

| Clean Room Monitoring | Rotary Vane Flow Meter | 1.0 | 1200 | 500 |

| Process Control | Differential Pressure Flow Meter | 0.5 | 1000 | 300 |

| Biotechnology | Ultrasonic Flow Meter | 0.8 | 1800 | 700 |

Integrating air flow meters with automation systems can significantly enhance monitoring capabilities and optimize performance in various industrial applications. According to a report by the International Society of Automation, the adoption of advanced flow measurement technology can lead to a 30% increase in system efficiency and a reduction in operational costs. This integration allows for real-time data collection and analysis, enabling businesses to make informed decisions and improve the overall reliability of their operations.

When incorporating air flow meters into automation systems, it is vital to ensure compatibility with existing infrastructure. Choosing the right communication protocols, such as Modbus or Ethernet/IP, can simplify the integration process. Additionally, regular calibration of flow meters is essential to maintain accuracy and prevent costly errors in measurement.

Tips: Regularly review your system's performance data to identify any discrepancies in flow measurements. Utilizing predictive maintenance techniques can also help you address potential issues before they escalate, thus ensuring uninterrupted operation. Finally, training staff on the proper usage and maintenance of air flow meters is crucial for maximizing the benefits of automation integration.

Proper maintenance of air flow meters is crucial for ensuring both accuracy and longevity in their performance. Regular calibration is one of the key aspects of maintenance; it ensures that the flow meter delivers precise measurements, which can significantly impact data reliability and operational efficiency. Routine checks should be scheduled to compare the readings against a known standard, and adjustments should be made as necessary. Additionally, any signs of wear or damage should be addressed promptly to prevent inaccuracies in future readings.

Another important maintenance tip is to keep the air flow meters clean. Dust, debris, and accumulated contaminants can obstruct the sensing elements or affect the flow path, leading to erroneous measurements. Implementing a cleaning schedule tailored to the operational environment will help maintain meter functionality. It is also advisable to review manufacturer guidelines for specific cleaning procedures and recommended frequencies, ensuring that all necessary components are thoroughly inspected and maintained. Regular maintenance and care will contribute significantly to the reliability and durability of air flow meters, ultimately supporting optimal performance in various applications.