-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

Choosing an Air Velocity Sensor is critical in various industries. Accurate measurements are vital for optimal performance. According to a recent report by the International Society of Automation, approximately 30% of air quality issues stem from inaccurate airflow measurements. This highlights the need for precision in selecting the right sensor.

Dr. Emily Thompson, a leading expert in environmental monitoring, emphasizes, "The right Air Velocity Sensor can drastically improve system efficiency." Her insights reflect the industry’s growing focus on sensor accuracy. Many professionals face challenges in sensor selection. Not all sensors provide the same level of accuracy or reliability. Real-world testing often reveals discrepancies in expected versus actual performance.

In a market filled with choices, differentiation becomes essential. Factors to consider include measurement range, response time, and environmental factors. The ideal sensor should fit specific application needs. Yet, many users overlook fundamental specifications. Feedback is crucial; users should not hesitate to share their experiences. Reflecting on feedback can guide the decision-making process.

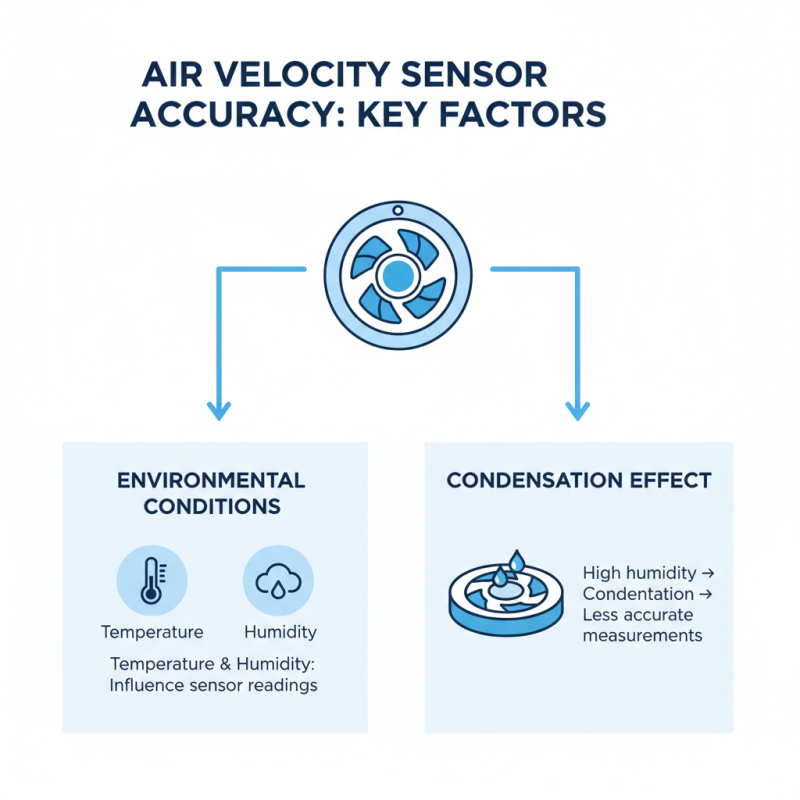

When choosing an air velocity sensor, understanding the factors affecting accuracy is crucial. Environmental conditions play a significant role. Temperature and humidity can influence sensor readings. For instance, high humidity may cause condensation on the sensor, leading to less accurate measurements.

Another factor is the position of the sensor. Ideally, it should be placed where the air flows smoothly. Obstructions can disrupt airflow, leading to erroneous data. Sensor calibration is equally important. Regular checks ensure that the sensor provides reliable readings.

**Tips:** Always consider the installation site. A clean, unobstructed area is best. Keep the sensor away from heat sources or vents. Regular maintenance is key. It may save costs in the long run. An overlooked detail could lead to a significant margin of error. Be meticulous during installation to enhance measurement accuracy.

Air velocity sensors come in various types, each with unique features and applications. Common types include hot-wire, pitot tube, and vane anemometers. Hot-wire sensors measure temperature changes due to airflow, making them suitable for low-velocity conditions. On the other hand, pitot tubes are often used in wind tunnels and aircraft due to their durability. Vane anemometers are practical for HVAC systems, providing easy-to-read measurements.

When choosing a sensor, consider the environment. Different sensors offer distinct advantages. For instance, pitot tubes excel in high-velocity areas, while hot-wire sensors perform well in controlled conditions. The learning curve for certain sensors might be steep. However, the effort pays off with accurate readings.

Tips: Always assess your measurements' accuracy needs. Look for sensors that offer calibration features. Don't overlook the importance of installation. Improper placement can lead to errors. Take time to understand the local airflow dynamics; it’s crucial for effective measurements.

When selecting an air velocity sensor, several key specifications warrant close attention. First, consider the measurement range. It’s crucial to choose a sensor that comfortably encompasses the airspeed you anticipate measuring. A sensor with too narrow a range might yield inaccurate readings. Also, sensitivity plays a vital role. A highly sensitive sensor can detect small fluctuations in air velocity, which is essential for precise applications.

Next, look into the sensor's response time. Fast response times are critical in fluctuating environments, like HVAC systems. Sensors with slower response times may miss significant changes, leading to misjudgments in airflow management. Data output formats also matter. Ensure the sensor is compatible with your data acquisition system. Sometimes, unusual formats can cause delays or require additional conversion equipment.

Another aspect is the environmental conditions where the sensor will be deployed. Humidity, temperature, and dust can impact performance. Not all sensors can withstand harsh conditions. Testing in various scenarios might be necessary, especially if you work in extreme environments. It’s a cliché, but often the best insights come from failures. Reviewing previous experiences can highlight what to avoid in future selections. Aim for a balance between precision and practicality.

Calibrating air velocity sensors is crucial for obtaining precise measurements. Due to environmental factors, drift can occur, affecting accuracy. Regular calibration ensures reliable data and maintains the sensor's integrity.

**Tips:** Ensure calibration is conducted in a controlled environment. Fluctuations in temperature and humidity can affect results. Use a reliable reference standard to enhance measurement consistency.

Another consideration is frequency. Sensors should be calibrated periodically as part of maintenance. This is particularly important in dynamic environments where air velocity can vary significantly.

**Tips:** Record calibration dates and results. This log helps identify patterns or trends over time. It also flags the need for recalibration due to consistent drift or deviations.

Lastly, beware of improper installation. If the sensor is not positioned correctly, it will deliver inaccurate readings. Obstructions and airflow patterns can distort data.

**Tips:** Install sensors away from obstacles and in clear airflow paths. Regularly check the installation to ensure it remains optimal.

| Sensor Type | Measurement Range (m/s) | Accuracy (%) | Response Time (ms) | Calibration Frequency (months) |

|---|---|---|---|---|

| Hot Wire Anemometer | 0.1 - 20 | ±2 | 100 | 6 |

| Pitot Tube | 0.5 - 30 | ±1.5 | 200 | 12 |

| Vane Anemometer | 0.5 - 25 | ±3 | 150 | 6 |

| Ultrasonic Anemometer | 0.1 - 60 | ±2 | 50 | 12 |

When selecting an air velocity sensor, industry standards play a crucial role in ensuring accuracy. The

American National Standards Institute (ANSI) publishes standards that guide testing methods.

These standards focus on the calibration processes required for sensors. Accurate calibration should not be underestimated.

According to a 2021 report by the International Society of Automation, up to 30% of

measurement errors stem from improper sensor calibration.

Regulations also shape air velocity measurements in various industries. For example, the

Occupational Safety and Health Administration (OSHA) mandates specific airflow measurements

in workplaces. Compliance with these regulations is not negotiable. A survey from a leading environmental agency

indicated that nearly 40% of companies failed to meet airflow standards. This lapse can lead to significant

health risks and operational inefficiencies.

Choosing the right sensor involves understanding these standards and regulations. It requires diligence in verifying

that sensors meet specific criteria. Uncertainties in your measurement tools can lead to flawed data. Ultimately,

continuous monitoring of industry standards

is essential. Striving for accurate measurements should be a constant pursuit for any professional in this field.