-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

Airflow measurement is a critical aspect of various industrial processes, maintaining efficiency and ensuring safety in a wide range of environments. At the heart of this measurement lies the technology of air velocity transmitters, which play a vital role in providing accurate and reliable data. These devices are designed to measure the speed of air moving through ducts and other ventilation systems, aiding in the optimization of HVAC systems, environmental monitoring, and laboratory applications.

Accurate airflow measurement is essential for maintaining air quality, energy efficiency, and effective process control. Air velocity transmitters offer precise readings that help facility managers and engineers identify potential issues before they escalate. By monitoring airflow, organizations can ensure that systems operate within their intended parameters, thereby reducing energy consumption and minimizing operational costs. Moreover, the reliability of air velocity transmitters can significantly impact compliance with standards and regulations, safeguarding both employee health and the environment.

In summary, air velocity transmitters are indispensable tools in achieving accurate airflow measurement. Their importance extends beyond mere data collection; they contribute to improved operational efficiency, safety, and environmental stewardship. This article will delve into the reasons why air velocity transmitters are essential tools in today's industrial landscape and how they empower organizations to make informed decisions based on precise airflow data.

Air velocity plays a crucial role in the efficiency and performance of HVAC systems. Proper airflow measurement ensures that heating, ventilation, and air conditioning systems operate effectively, maintaining optimal comfort levels in residential and commercial spaces. When air velocity is accurately measured, it enables better control of temperature, humidity, and air quality, directly impacting the well-being of occupants.

Moreover, precise air velocity readings help in diagnosing problems within HVAC systems, such as duct leaks or blockages, which can lead to energy inefficiency and increased operational costs. By utilizing air velocity transmitters, technicians can identify discrepancies in airflow and adjust system settings accordingly. This not only enhances energy efficiency but also prolongs the lifespan of the HVAC equipment, ensuring it operates at peak performance while reducing the likelihood of costly repairs.

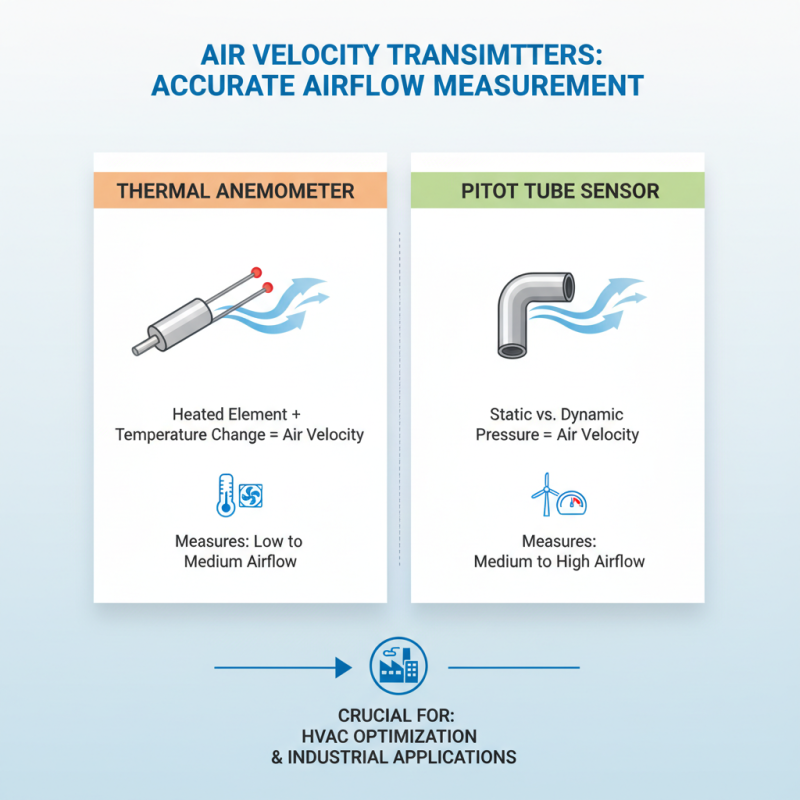

Air velocity transmitters play a crucial role in the precise measurement of airflow by employing various technologies to ensure accurate readings. These devices typically utilize either thermal or pitot tube principles to determine the speed of air moving through a conduit or open space. In thermal sensors, an electrically heated element is placed in the airflow, and the change in temperature caused by the movement of air around it is directly correlated to the velocity of that air. Conversely, pitot tube sensors measure the pressure difference between static and dynamic air pressures to calculate velocity. Both methods deliver vital data that supports efficient HVAC operations and ensures optimal performance in various industrial applications.

The operation of air velocity transmitters involves the continuous monitoring of air parameters. Once the sensor captures relevant airflow data, it converts these measurements into electrical signals that can be easily interpreted by control systems or displayed on meters. Many modern transmitters incorporate advanced algorithms to filter out interference and enhance measurement accuracy in dynamic environments. Moreover, with the integration of wireless technologies, real-time data can be transmitted to central monitoring systems, allowing for proactive adjustments to ventilation strategies and energy consumption. This functionality exemplifies how air velocity transmitters not only contribute to measurements but also improve operational efficiency and environmental control.

Air velocity transmitters play a critical role in various industries by providing precise measurements that are vital for ensuring system efficiency and safety. One of the key applications of these devices can be found in HVAC (Heating, Ventilation, and Air Conditioning) systems. Accurate airflow measurement helps in maintaining optimal indoor air quality, energy efficiency, and comfort levels. By monitoring air velocity, facilities can adjust dampers and fans to enhance airflow distribution, ultimately reducing energy consumption and costs.

Another significant application is in environmental monitoring and control. In cleanrooms and laboratories, air velocity transmitters ensure that contamination is minimized by maintaining specific airflow patterns. This is crucial in settings such as pharmaceutical manufacturing and semiconductor production, where even slight variations in air movement can compromise product integrity. Additionally, air velocity transmitters are used in ductwork systems for industrial processes to monitor and control emissions, contributing to better environmental compliance and safety standards.

The following chart illustrates the typical airflow measurements in various applications where air velocity transmitters are essential. These applications include HVAC systems, clean rooms, and industrial processes.

Airflow measurement is critical in various industrial applications, and the choice between manual and automated methods can significantly impact accuracy and efficiency. Manual airflow measurement often involves using devices like pitot tubes or anemometers, which require skilled operators to read and interpret data. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), manual measurements can present issues with human error, leading to inaccuracies that can range from 5% to 15%. This variation not only affects system performance but can also lead to unnecessary energy consumption and operational inefficiencies.

In contrast, automated airflow measurement systems, equipped with air velocity transmitters, provide continuous and precise data collection. A study by the National Institute of Standards and Technology (NIST) highlighted that automated systems improve data accuracy by approximately 20-30%, allowing for better insight into airflow patterns and system behavior. Automated systems also reduce the labor costs associated with manual measurements, as they minimize the need for frequent on-site checks.

Tips: When selecting an airflow measurement system, consider the specific needs of your application. For instance, if your environment requires real-time monitoring, automated solutions would be more advantageous. Additionally, always ensure that calibration is conducted regularly to maintain the reliability of any measurement system you choose. Finally, invest in training personnel to understand automation benefits, ensuring optimal data utilization and system performance.

Calibration and maintenance are crucial components in ensuring the accuracy of air velocity transmitters, which are essential tools for measuring airflow in various applications. Calibration involves comparing the output of the transmitter against a known standard, allowing for adjustments to be made to ensure that the readings are precise. Regular calibration schedules help identify any drift in measurements over time, which can result from environmental factors or wear and tear of the transmitter itself. Without proper calibration, the reliability of airflow measurements can be compromised, leading to suboptimal system performance and potential safety hazards.

In addition to calibration, routine maintenance is vital for the long-term performance of air velocity transmitters. This includes cleaning sensor elements to prevent buildup that could affect measurements and checking wiring connections for damage or corrosion. Visual inspections and functional tests should be part of an ongoing maintenance program to catch any potential issues before they escalate. Properly maintained transmitters not only provide accurate measurements but also enhance the overall efficiency of systems relying on airflow regulation, ultimately leading to energy savings and improved operational reliability.

| Parameters | Importance | Frequency of Calibration | Best Practices for Maintenance |

|---|---|---|---|

| Air Velocity | Critical for HVAC efficiency and system performance | Every 6 months | Regularly check sensor alignment and clean probes |

| Airflow Measurement | Ensures proper air distribution and comfort | Annually | Inspect electrical connections and software updates |

| Temperature Compensation | Enhances measurement accuracy | Every 3 months | Monitor environmental changes |

| Pressure Considerations | Affects flow rate calculations | Bi-annually | Ensure pressure elements are functional |

| Calibration Methods | Ensures accuracy and reliability | As needed | Use known flow rates for validation |